2023 3D Printer Buying Guide: All You Need to Know

1. Introduction:

a. What is 3D printing?

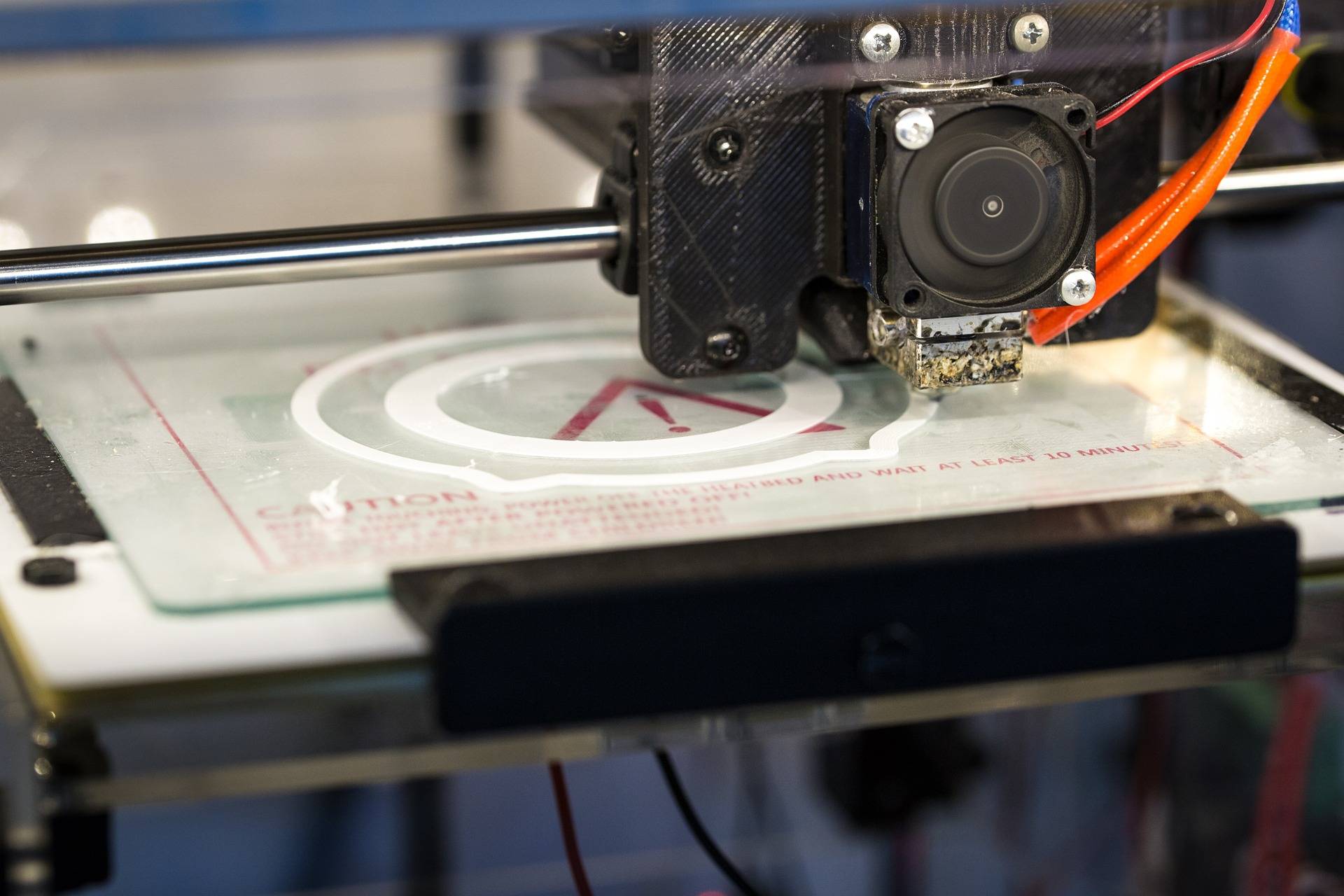

3D printing, also known as additive manufacturing, is a revolutionary technology that has transformed the way we create physical objects. At its core, 3D printing is a process of building three-dimensional objects layer by layer, directly from a digital model or design. Unlike traditional manufacturing methods that involve subtractive processes like cutting or molding, 3D printing adds material layer by layer to create the final product.

The process of 3D printing begins with a 3D model created using computer-aided design (CAD) software or obtained from a 3D scanner. The digital model is then sliced into thin cross-sectional layers, which are sent to the 3D printer. The printer interprets each layer and precisely deposits or solidifies the material to build the object from the bottom up.

B. History and Evolution of 3D printing Technology

In the realm of modern manufacturing, few technologies have had as profound an impact as 3D printing. The history and evolution of 3D printing have been a remarkable journey of innovation and technological progress. From its early beginnings to the recent breakthroughs, 3D printing has transformed various industries and opened up new frontiers in manufacturing.

Origins of 3D Printing:

The roots of 3D printing can be traced back to the 1980s when the concept of additive manufacturing started taking shape. Early pioneers recognized the potential of creating objects layer by layer, envisioning a technology that could revolutionize traditional manufacturing processes.

A Brief History of Major 3D Printing Milestones:

1. 1984: Stereolithography (SLA) - Charles W. Hull introduced the first 3D printing technology, SLA, which used photopolymerization to solidify liquid resin into solid objects.

2. 1992: Selective Laser Sintering (SLS) - Carl Deckard developed SLS, a technique that utilized a high-powered laser to selectively fuse powdered materials into a solid form.

3. 1999: Fused Deposition Modeling (FDM) - Scott Crump invented FDM, a method that extrudes thermoplastic materials layer by layer, popularizing affordable 3D printers.

4. 2005: RepRap - The RepRap project was launched, pioneering the concept of self-replicating 3D printers and promoting open-source collaboration within the 3D printing community.

5. 2009: Digital Light Processing (DLP) - DLP emerged as an alternative to SLA, utilizing digital micromirrors to project light and solidify resin, enabling faster printing speeds.

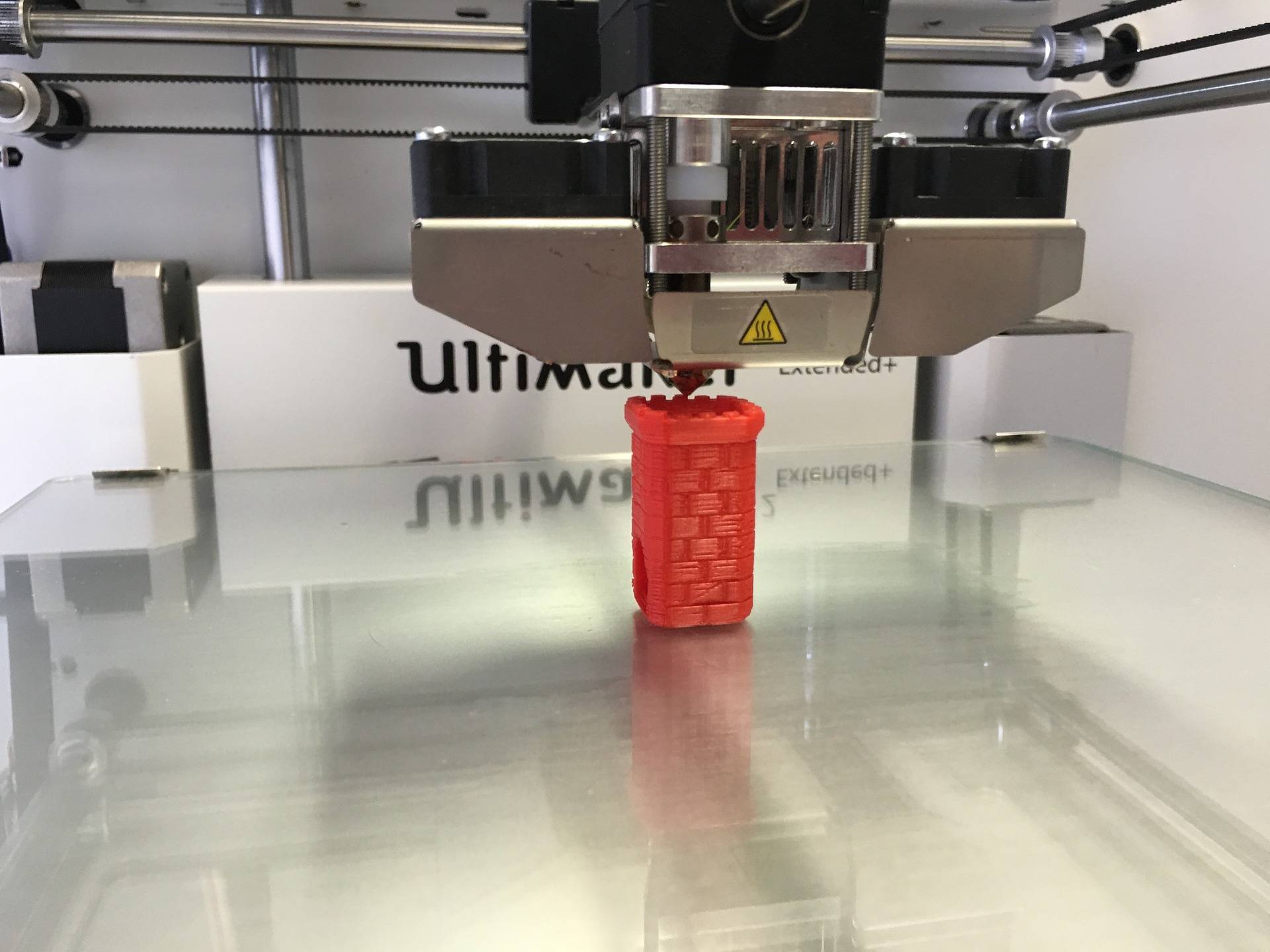

6. 2010: Desktop 3D Printers - Companies like MakerBot and Ultimaker introduced affordable and user-friendly desktop 3D printers, making the technology accessible to a wider audience.

7. 2013: Metal 3D Printing - Advances in metal 3D printing techniques, such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), opened up possibilities for producing complex metal parts.

Recent Advancements in 3D Printing Technology:

1. High-Speed 3D Printing - Researchers have developed faster printing techniques, incorporating multiple print heads, parallel processing, and improved material formulations.

2. Multi-Material and Multi-Color Printing - 3D printers can now seamlessly switch between different materials and colors during a single print, expanding the range of possibilities.

3. Bioprinting and Tissue Engineering - Scientists are exploring the realm of bioprinting, where living cells and biomaterials are used to create functional human tissues and organs.

4. Large-Scale 3D Printing - Advancements in gantry systems and robotic arms have enabled the printing of massive structures, including buildings and infrastructure components.

5. Sustainability and Recycled Materials - The 3D printing community is actively exploring eco-friendly materials and recycling methods to minimize waste and promote sustainability.

2. The Possibilities of 3D Printing

A. Benefits of 3D Printing

The benefits of 3D printing are transforming industries and driving innovation across the globe. From cost savings and customization to faster prototyping and sustainable manufacturing, the advantages offered by this technology are reshaping the way we think about production.

1.Cost Savings

One of the significant advantages of 3D printing is its potential for cost savings. Traditional manufacturing methods often involve complex processes, expensive tooling, and substantial material waste. In contrast, 3D printing allows for on-demand production, eliminating the need for expensive molds or tooling. With 3D printing, intricate designs can be realized without incurring additional costs, making it particularly advantageous for low-volume or customized production.

2.Customization and Design Freedom

3D printing empowers designers and engineers with unparalleled design freedom and customization capabilities. Unlike traditional manufacturing methods that impose limitations on geometries and structures, 3D printing enables the creation of complex and intricate designs. This freedom allows for highly personalized and tailored products, making it ideal for creating custom prosthetics, dental implants, and unique consumer goods.

3.Faster Prototyping and Time-to-Market

In traditional manufacturing, prototyping can be a time-consuming and costly process. With 3D printing, rapid prototyping becomes a reality. Design iterations can be quickly produced, tested, and refined, significantly reducing the time-to-market for new products. This agility enables businesses to stay ahead of the competition, respond to market demands faster, and accelerate innovation cycles.

4.Reduced Material Waste and Sustainability

Traditional manufacturing often generates significant material waste due to subtractive processes. In contrast, 3D printing follows an additive approach, where material is deposited layer by layer, resulting in minimal waste. Additionally, 3D printing allows for the use of recycled or eco-friendly materials, further promoting sustainability in manufacturing.

5.Complex Structures and Lightweight Designs

The ability of 3D printers to create complex structures with internal cavities and intricate geometries opens up new possibilities for lightweight designs. This advantage is particularly relevant in industries such as aerospace and automotive, where weight reduction directly translates into improved fuel efficiency and performance.

6.On-Demand Manufacturing and Supply Chain Optimization

3D printing has the potential to revolutionize supply chains by enabling on-demand manufacturing. Instead of maintaining extensive inventories, products can be printed as needed, reducing warehousing costs and inventory management complexities. This flexibility allows for localized production, minimizing transportation and reducing the carbon footprint associated with long-distance shipping.

7.Innovations in Medicine and Healthcare

The impact of 3D printing on the medical field has been profound. It has facilitated advancements in personalized medicine, prosthetics, surgical planning, and organ transplantation. Customized medical implants, patient-specific anatomical models, and bioprinting of tissues and organs are revolutionizing healthcare by enhancing patient outcomes and improving the quality of care.

As 3D printing continues to evolve and mature, we can expect even more remarkable applications and advantages to emerge, further propelling us into a future where the impossible becomes possible.

B. Applications of 3D printing in different industries

The applications of 3D printing offer personal hobbyists and individual consumers a range of exciting possibilities. 3D printing technology has revolutionized the way individuals can create, customize, and innovate in various aspects of their lives. Here are some notable applications of 3D printing for personal consumers:

1.Personalized Products

With 3D printing, you can create personalized and customized products tailored to your specific preferences. From jewelry and accessories to home decor items, 3D printers enable users to design and fabricate unique pieces that reflect their individual style and taste.

2.Prototyping and DIY Projects

3D printing empowers hobbyists and DIY enthusiasts to bring their ideas to life. Whether it's prototyping a new invention, building custom gadgets, or constructing models for various projects, 3D printers provide a cost-effective and efficient way to produce functional prototypes and physical objects at home.

3.Home Improvement and Repairs

3D printing can be a valuable tool for home improvement projects and repairs. Need a replacement knob for your drawer or a custom-designed bracket to fix a broken shelf? 3D printing allows you to design and fabricate these small parts and components quickly and easily, saving time and money.

4.Educational Tools and Models

3D printing is revolutionizing education by enabling the creation of interactive models and visual aids. Students can explore complex concepts through tactile learning experiences, as educators utilize 3D printers to produce educational tools, anatomical models, scientific prototypes, and more.

5.Artistic Expression

Artists and creative individuals can leverage 3D printing to push the boundaries of artistic expression. The technology allows for the fabrication of intricate sculptures, installations, and art pieces with precision and detail. Artists can experiment with new materials and designs, exploring previously unattainable artistic possibilities.

6.Fashion and Accessories

3D printing offers a new realm of possibilities in the world of fashion and accessories. Designers and consumers can create unique, avant-garde fashion pieces, jewelry, and accessories that stand out from traditional mass-produced items. Customization is a key aspect, as 3D printing enables you to design and produce fashion items that perfectly fit your body measurements and personal style.

7.Gaming and Collectibles

Gaming enthusiasts and collectors can benefit from 3D printing by creating customized figurines, game accessories, and collectible items. With a 3D printer, you can design and manufacture your favorite characters or unique game components, adding a personal touch to their gaming experience.

C. Examples of impressive and innovative 3D printing projects

1. Customized Car Accessories and Upgrades

For automotive enthusiasts, 3D printing opens up opportunities to create customized car accessories and upgrades. Hobbyists can design and print personalized interior parts, such as dashboard accents, custom shift knobs, or unique air vent covers. With 3D printing, intricate and complex geometries can be easily realized, allowing for the creation of lightweight components that enhance fuel efficiency and performance. This empowers individuals to personalize and enhance their driving experience.

2.Miniature Architectural Models and Home Decor

3D printing enables hobbyists to dive into the world of architecture and interior design by creating intricate miniature models and unique home decor pieces. Using specialized software, individuals can design and print detailed architectural models, showcasing their creativity and exploring various design concepts. Additionally, 3D printing offers the opportunity to produce customized home decor items, such as decorative sculptures, personalized wall art, or intricate lampshades, allowing hobbyists to add a touch of their own style to their living spaces.

3.Artistic Creations and Personalized Crafts

3D printing serves as a powerful tool for artistic expression and personalized craftsmanship. Hobbyists can bring their artistic designs to life by printing intricate sculptures, figurines, or ornamental pieces with exceptional detail and precision. The versatility of 3D printing allows for experimentation with various materials, textures, and colors, enabling individuals to explore unique artistic expressions and create truly one-of-a-kind artworks. From intricate jewelry pieces to personalized decorative crafts, 3D printing empowers hobbyists to unleash their creativity.

4.Customized Fashion Accessories and Wearables

Individuals with a passion for fashion can leverage 3D printing to design and produce their own customized accessories and wearables. By pushing the boundaries of design, hobbyists can create unique and unconventional fashion pieces, such as avant-garde jewelry, statement-making headpieces, or intricate belt buckles. 3D printing technology enables the realization of complex shapes and allows for the use of a wide range of materials, allowing individuals to express their personal style through personalized fashion creations.

These examples represent just a fraction of the impressive and innovative projects made possible by 3D printing for personal hobbyists. Whether it's creating personalized prosthetics, designing customized car accessories, crafting artistic pieces, or exploring unique fashion statements, 3D printing continues to empower individuals to unleash their creativity and push the boundaries of what is possible in their personal pursuits.

D. Comparison of 3D printing to traditional manufacturing methods

3D printing offers a range of unique advantages that set it apart from traditional manufacturing techniques such as injection molding, CNC machining, and casting. In this article, we delve into the comparison between 3D printing and these traditional methods, highlighting the distinctive benefits and considerations of each.

1.Injection Molding

Injection molding has been a staple in mass production for decades. It involves injecting molten material into a mold cavity to create a desired shape. While injection molding offers high production volumes and excellent surface finish, it can be costly and time-consuming to create molds, especially for low-volume or custom-designed products. On the other hand, 3D printing excels in rapid prototyping and low-volume production, eliminating the need for molds. With 3D printing, designs can be easily modified and produced without the upfront expenses associated with mold creation. However, injection molding still holds an advantage in large-scale production where unit costs can be significantly lower.

2.CNC Machining

Computer Numerical Control (CNC) machining is a subtractive manufacturing process that involves cutting away material from a solid block to achieve the desired shape. CNC machines offer high precision and can produce complex parts from a wide range of materials. However, CNC machining is a time-consuming process, requiring multiple setup steps and extensive machining time. In contrast, 3D printing eliminates the need for complex setups and reduces the overall production time. It is particularly advantageous for creating intricate geometries that would be challenging or costly to achieve through CNC machining. 3D printing also allows for the production of parts with internal structures and cavities that would be difficult or impossible to machine.

3.Casting

Casting is a traditional manufacturing technique that involves pouring molten material into a mold, which then solidifies to create the desired shape. Casting offers versatility in producing complex shapes and is well-suited for materials like metals and certain plastics. However, the process often requires the creation of custom molds, which can be time-consuming and expensive. 3D printing provides an alternative by enabling the direct production of intricate molds or even the final parts themselves. This flexibility reduces lead times and allows for design iterations without the need for costly tooling. 3D printing is particularly advantageous for small-scale production, customization, and producing complex geometries that would be challenging to achieve through traditional casting methods.

It is important to note that while 3D printing offers significant advantages in terms of design flexibility, customization, and rapid prototyping, traditional manufacturing methods still excel in certain areas, such as large-scale production and cost-effectiveness for high-volume runs. Each method has its strengths and considerations, and the choice of manufacturing technique depends on the specific requirements of the project, including volume, material, complexity, and time constraints.

As technology continues to advance, we can expect further innovations and improvements in both 3D printing and traditional manufacturing methods. The key lies in understanding the unique capabilities of each approach and leveraging them to achieve the best outcomes in terms of quality, efficiency, and cost-effectiveness. By embracing the strengths of each method, manufacturers can unlock new possibilities and drive innovation in the ever-evolving landscape of manufacturing.

E. Future of 3D printing

As 3D printing technology continues to advance, it opens up a world of limitless possibilities for personal hobbyists. This remarkable technology, also known as additive manufacturing, is set to undergo further advancements in materials, speed, and accessibility, driving its widespread adoption among individuals.

1.Advancements in Materials

A key area of focus for the future of 3D printing lies in the expansion and diversification of available materials. Ongoing research and development promise a broader range of options beyond plastics, metals, and ceramics. Hobbyists can look forward to the emergence of new materials with enhanced properties, such as improved strength, durability, flexibility, and even conductive or bio-compatible characteristics. This opens up exciting opportunities for innovative projects in various fields, from model-making and crafts to personalized wearable items.

2.Speed and Efficiency

Speed has been a consideration for 3D printing, but ongoing advancements are addressing this limitation. The future holds the promise of faster printing speeds through improved hardware and optimized software algorithms. These developments will enhance productivity and allow hobbyists to create more complex objects within reasonable timeframes. Additionally, the efficiency and scalability of 3D printing technology are expected to improve, enabling simultaneous printing of multiple objects or the seamless integration of multiple printers for larger projects.

3.Democratization of Manufacturing

As the cost of 3D printing technology continues to decrease, and the accessibility and user-friendliness improve, it will become increasingly democratized. This means that personal hobbyists, small businesses, and entrepreneurs will have the power to bring their ideas to life. Customized, on-demand production will become the norm, revolutionizing the way individuals create and innovate. The integration of 3D printing with other emerging technologies will further enhance its capabilities and create new possibilities for personal projects.

4.Enhanced Resolution and Precision

In the future, advancements in 3D printing technology will focus on improving the resolution and precision of printed objects. Higher resolution will enable hobbyists to produce more intricate and detailed designs with greater accuracy. This will result in smoother surfaces, finer textures, and improved overall quality of printed objects. The increased precision will allow for the creation of complex geometries and delicate structures, unlocking new possibilities for artistic expression and precision engineering.

5.Integration of Multi-Material Printing

Another area of future advancement is the integration of multi-material printing capabilities. Currently, most desktop 3D printers are limited to printing with a single material at a time. However, ongoing research aims to enable printers to seamlessly switch between different materials during the printing process. This will allow hobbyists to create objects with varying material properties, colors, and textures in a single print job. The ability to combine materials opens up endless opportunities for creating unique and functional objects with customized properties.

6.Improved Post-Processing

Techniques Post-processing, which involves refining and finishing the printed objects, is an essential part of the 3D printing workflow. Future advancements will focus on developing more efficient and user-friendly post-processing techniques. This includes innovations in automated support removal, surface finishing, and coloring methods. Streamlining the post-processing steps will reduce the time and effort required to achieve the desired final result, making the entire printing process more convenient and accessible for hobbyists.

7.Integration with Augmented Reality (AR) and Virtual Reality (VR)

The integration of 3D printing with augmented reality (AR) and virtual reality (VR) technologies holds great potential for the future. AR and VR can be used to enhance the design and visualization process, allowing hobbyists to interact with their virtual models before printing them. This integration will enable more intuitive design workflows, where creators can make real-time modifications and adjustments in a virtual environment. Additionally, AR and VR can be utilized to provide step-by-step guidance during the printing process, simplifying complex tasks and ensuring successful outcomes.

8.Advancements in Software and Design Tools

The future of 3D printing will also see significant advancements in software and design tools. Software algorithms will continue to improve, offering more sophisticated slicing and modeling capabilities. This will enable hobbyists to optimize print settings, enhance object strength and stability, and achieve better overall print quality. Additionally, user-friendly design software and intuitive interfaces will make it easier for beginners to create and modify 3D models, empowering more individuals to engage in 3D printing as a hobby.

As the future unfolds, 3D printing will continue to empower personal hobbyists by providing access to a broader range of materials, increasing printing speeds, and enabling on-demand, customized production. The convergence of innovation and opportunity will reshape the personal hobbyist landscape, allowing for groundbreaking projects and the realization of creative visions. Embrace the potential of 3D printing, and embark on an exciting journey where the boundaries of imagination and personal manufacturing are pushed to new frontiers.

3. Choosing the Right 3D Printer

A. Types of 3D Printers

When it comes to 3D printing, there are various types of printers available, each utilizing different technologies and processes to bring your designs to life. Understanding the different types of 3D printers can help you make an informed decision based on your specific requirements and desired outcomes. Here are some of the most common types of 3D printers:

1.Fused Deposition Modeling (FDM)

FDM is the most widely used 3D printing technology. It operates by melting a thermoplastic filament and extruding it layer by layer to create the object. FDM printers are known for their affordability, ease of use, and wide range of compatible materials. They are suitable for hobbyists, educators, and professionals seeking to produce functional prototypes, household objects, and small-scale models.

2.Stereolithography (SLA)

SLA printers use a liquid resin that is cured layer by layer using a UV light source. This technology produces high-resolution prints with smooth surface finishes, making it popular in industries such as jewelry, dentistry, and prototyping. SLA printers are capable of producing intricate details and complex geometries, but they typically come with a higher price tag.

3.Digital Light Processing (DLP)

Similar to SLA, DLP printers use a vat of liquid resin that is cured using a digital light projector. DLP printers offer faster print speeds compared to SLA and can achieve high levels of detail. They are suitable for applications that require precise details and rapid prototyping.

4.Selective Laser Sintering (SLS)

SLS printers utilize a high-powered laser to selectively fuse powdered materials, such as plastics, metals, or ceramics, layer by layer. This technology enables the production of complex and functional parts with excellent mechanical properties. SLS printers are commonly used in industries like aerospace, automotive, and healthcare for creating durable end-use parts and functional prototypes.

5.Binder Jetting

In binder jetting, a liquid binding agent is selectively deposited onto layers of powdered material, such as sand or metal, to create the object. This process is often used for rapid prototyping, creating intricate models, and producing objects with a high level of detail. Binder jetting is also employed in industries like architecture, art, and product design.

Each type of 3D printer offers its own set of advantages and considerations. Factors to consider when choosing a printer include print quality, resolution, speed, material compatibility, cost, and the intended application of the printed objects. By understanding the capabilities and limitations of each type, you can select the most suitable 3D printer that aligns with your project requirements and budget.

B. Considerations When Choosing a 3D Printer

Choosing the right 3D printer for your needs can be an exciting yet challenging endeavor. As the market offers a wide range of options, it's important to carefully consider several factors to ensure you make an informed decision.

1.Purpose and Intended Use

The first step in choosing a 3D printer is to define your purpose and intended use. Are you a hobbyist looking to create small-scale projects, an educator seeking to enhance classroom learning, or a professional in need of high-precision industrial applications? Understanding your specific use case will help determine the required features, build volume, resolution, and material compatibility needed for your projects.

2.Budget and Cost of Ownership

Establishing a budget is crucial when considering a 3D printer. The cost can vary significantly depending on the technology, build quality, features, and brand. It's essential to not only consider the upfront cost of the printer but also the ongoing expenses associated with maintenance, filament or material costs, and potential upgrades. Evaluating the total cost of ownership will ensure you make a financially viable choice that aligns with your budgetary constraints.

3.Build Volume and Print Size

The build volume of a 3D printer refers to the maximum dimensions of the objects it can print. Assessing your project requirements and the size of objects you intend to create is crucial. If you anticipate working on larger-scale projects, you'll need a printer with a larger build volume. However, if your projects involve smaller parts or intricate details, a smaller build volume may suffice. Finding the right balance between size and functionality is key to avoid limitations and optimize your printing capabilities.

4.Ease of Use and User Experience

Consider the user-friendliness and overall user experience offered by the 3D printer. Look for features such as touchscreen interfaces, intuitive software, and ease of setup and calibration. A well-designed and user-friendly printer can save time and frustration, especially for beginners or those with limited technical expertise. Additionally, access to comprehensive documentation, customer support, and a supportive community can greatly enhance your overall 3D printing journey.

5.Connectivity and Software Compatibility

Evaluate the connectivity options and software compatibility of the 3D printer. USB, Wi-Fi, or Ethernet connectivity can offer convenience in file transfer and remote monitoring. Compatibility with popular slicing software, such as Ultimaker Cura, PrusaSlicer, or Simplify3D, ensures a seamless workflow and access to advanced features for optimized printing.

6.Printing Speed and Efficiency

The printing speed of a 3D printer can vary significantly depending on the technology and model. Consider the desired turnaround time for your projects and evaluate the speed capabilities of the printers you're considering. It's worth noting that faster printing speeds may come at the cost of reduced print quality, so finding the right balance is important.

7.Filament Compatibility and Material Options

Different 3D printers support different types of filaments or materials. While many printers are compatible with standard filaments like PLA and ABS, if you have specific material requirements such as flexible filaments, high-performance engineering materials, or even specialized composite materials, ensure that the printer you choose can accommodate those materials.

8.Build Quality and Durability

Assess the build quality and durability of the 3D printer. Look for printers constructed from sturdy materials that can withstand continuous use and provide stability during the printing process. A robustly built printer will generally offer better long-term reliability and produce more consistent results.

9.Noise Level

Consider the noise level produced by the 3D printer, especially if you plan to use it in an office or home environment. Some printers operate quietly, while others can be relatively noisy. If noise is a concern, look for printers with noise reduction features or enclosed printing chambers to minimize sound.

10.Safety Features

Prioritize the safety features offered by the 3D printer. Look for features such as thermal runaway protection, filament runout detection, and automatic bed leveling. These features not only ensure safer operation but also contribute to better print quality and reliability.

11.Expansion and Upgradability

Consider the potential for expansion and upgradability of the 3D printer. Some printers offer modular designs that allow for future enhancements or upgrades, such as improved extruders, heated build plates, or even dual extrusion capabilities. Assessing the upgrade options can future-proof your investment and provide flexibility for evolving needs.

12.Calibration and Maintenance

Consider the calibration process and maintenance requirements of the 3D printer. Some printers may require frequent calibration to ensure optimal print quality, while others have automated calibration systems. Additionally, assess the ease of maintenance and availability of spare parts or customer support to address any potential issues that may arise.

13.Software and Firmware Updates

Check for regular software and firmware updates provided by the manufacturer. Keeping your printer's software up to date can improve performance, introduce new features, and address any bugs or security vulnerabilities. Look for printers with an active community or manufacturer support that actively releases updates.

14.Print Quality and Resolution

Evaluate the print quality and resolution capabilities of the printer. Consider the layer height options, which determine the level of detail and smoothness achievable in your prints. Higher resolution capabilities allow for finer details and smoother surfaces, but it may also increase printing time.

15.Power and Energy Efficiency

Assess the power requirements and energy efficiency of the 3D printer. Some printers may consume more power during operation, while others have energy-saving features. Consider the power consumption in relation to your usage patterns and environmental considerations.

16.Additional Features and Accessories

Explore any additional features and accessories that come with the 3D printer. This could include features like a heated build plate for better adhesion, a built-in camera for remote monitoring, or a filament detection sensor. Assess whether these features align with your specific needs and add value to your printing experience.

17.Reviews and User Feedback

Research and read reviews from other users who have experience with the specific printer models you're considering. User feedback can provide insights into real-world performance, reliability, and any potential issues to be aware of. Look for reviews from reputable sources or join online communities to gather more information and make an informed decision.

By considering these key factors, you can narrow down your options and find a 3D printer that aligns with your specific requirements. Remember that thorough research, reading user reviews, and seeking recommendations from trusted sources can provide valuable insights into the performance, reliability, and overall satisfaction of different printer models. Ultimately, choosing the right 3D printer will empower you to bring your ideas to life and embark on an exciting journey of creative exploration.

B. Considerations When Choosing a 3D Printer

While a reliable 3D printer forms the foundation of your printing setup, there are various accessories and upgrades available that can enhance your overall 3D printing experience. Below are a range of accessories and upgrades that can take your prints to the next level and make your journey in the world of 3D printing even more rewarding.

1.Filaments and Materials

One of the key considerations in 3D printing is the choice of filaments and materials. While most printers come with a standard filament, exploring different materials can expand your creative possibilities. Experimenting with filaments like PLA, ABS, PETG, or specialty filaments such as wood-infused or flexible materials can offer unique textures, finishes, and functional properties. Additionally, upgrading to high-quality filaments from reputable manufacturers can significantly improve print quality and reliability.

2.Nozzles

The nozzle is a critical component of a 3D printer, responsible for extruding the filament and determining the printing resolution. Upgrading to a nozzle with a smaller diameter can enhance the level of detail in your prints, allowing for finer and more intricate designs. Conversely, a larger nozzle diameter can increase print speed for larger-scale projects. Swappable nozzles also enable you to optimize your printing setup based on specific requirements.

3.Print Surface

Ensuring proper adhesion of your prints to the print bed is essential for successful 3D printing. Upgrading the print surface can enhance bed adhesion and reduce the chances of warping or detachment during printing. Popular options include glass beds, specialized adhesive sheets, or magnetic flexible build plates. Each option offers unique benefits such as improved flatness, ease of print removal, or enhanced compatibility with specific materials.

4.Cooling Fans

Efficient cooling plays a crucial role in achieving high-quality prints, particularly for designs with intricate details or overhangs. Upgrading or adding additional cooling fans can improve print accuracy by preventing filament overheating and minimizing stringing or blobbing. Directing airflow to the print area effectively dissipates heat, resulting in cleaner, more precise prints.

5.Print Monitoring and Control

Remote monitoring and control of your 3D printer can provide convenience and peace of mind. Upgrading to a printer with built-in Wi-Fi connectivity or adding an aftermarket module allows you to monitor print progress, adjust settings, and receive real-time notifications from anywhere using your smartphone or computer. Additionally, camera modules can provide visual monitoring, enabling you to keep an eye on your prints remotely.

6.Software and Firmware Upgrades

Software plays a crucial role in the 3D printing process. Keeping your slicing software, firmware, and printer drivers up to date ensures access to the latest features, bug fixes, and performance improvements. Regularly updating your software and firmware can enhance print quality, reliability, and overall user experience. Exploring different slicing software options can also unlock advanced features and customization options tailored to your specific needs.

7.Toolkits and Maintenance Accessories

Having the right tools and accessories for maintenance and post-processing can greatly enhance your 3D printing workflow. Toolkits with various spatulas, pliers, wire cutters, and precision tools aid in print removal, support removal, and general maintenance tasks. Additionally, investing in a digital caliper enables accurate measurements and calibration adjustments, resulting in precise prints.

By exploring and investing in these accessories and upgrades, you can elevate your 3D printing experience and unlock new levels of creativity and functionality. Whether it's experimenting with different materials, optimizing print bed adhesion, or upgrading cooling and control systems, each enhancement contributes to achieving higher-quality

4.How To Set Up A 3D Printer?

Step 1: Unboxing and Inspection

Carefully unbox your 3D printer and inspect all the components for any signs of damage that may have occurred during shipping. Ensure that all the necessary parts, including the printer, power cables, filament, tools, and instruction manual, are present. Take the time to read through the instruction manual thoroughly before proceeding.

Step 2: Selecting a Suitable Location

Find a suitable location for your 3D printer. Ideally, choose a well-ventilated area away from direct sunlight and drafts. It's also important to consider the noise level produced by the printer, as well as any safety precautions such as keeping it out of reach of children or pets.

Step 3: Assembling the Printer

Follow the manufacturer's instructions to assemble the various components of your 3D printer. This typically involves attaching the frame, bed, extruder, and other key elements. Pay close attention to the specific instructions for your printer model, as assembly steps can vary.

Step 4: Leveling the Print Bed

Properly leveling the print bed is crucial for ensuring successful prints. Most 3D printers have manual or automatic bed leveling features. If your printer requires manual leveling, carefully adjust the bed using the provided knobs or screws until it is level at all corners and the center. Automatic leveling systems typically involve following on-screen prompts to calibrate the bed.

Step 5: Installing Filament

Insert the filament into the extruder following the manufacturer's guidelines. Feed the filament through the filament guide tube (if applicable) and into the extruder until it reaches the nozzle. Ensure that the filament is securely inserted and properly aligned.

Step 6: Connecting to Power

Connect the power cable to your 3D printer and plug it into a reliable power source. Check that the power switch is turned off before connecting the printer to avoid any accidental movement or operation during setup.

Step 7: Connecting to a Computer or Network

If your printer requires a computer connection, connect it via USB or Wi-Fi according to the manufacturer's instructions. Install any necessary drivers or software provided by the manufacturer. Some printers offer standalone operation with an onboard interface, eliminating the need for a computer connection.

Step 8: Calibrating and Testing

Power on your 3D printer and navigate through the menu or software interface to access the calibration and testing options. Follow the instructions to perform a calibration routine, which typically involves adjusting the nozzle height, bed leveling, and filament loading. Once calibration is complete, perform a test print to ensure that the printer is functioning correctly.

Step 9: Learning and Experimenting

With your 3D printer set up and calibrated, it's time to start learning and experimenting! Familiarize yourself with the slicing software used to prepare your 3D models for printing. Explore different settings, such as layer height, print speed, and infill density, to achieve the desired print quality. Begin with simple models and gradually progress to more complex designs as you gain confidence and experience.

Remember, 3D printing is a continuous learning process, and troubleshooting is part of the journey. Take advantage of online resources, forums, and communities to seek guidance, share experiences, and expand your knowledge.

5. Safety Considerations

When using a 3D printer, it's important to be aware of safety considerations to ensure a secure and risk-free printing experience. While 3D printers are generally safe to use, understanding potential hazards and taking necessary precautions can help prevent accidents and protect your well-being. Here are some key safety considerations to keep in mind:

1. Ventilation

3D printers can emit fumes and particles during the printing process, especially when using certain materials like ABS or nylon. Ensure that your printing area is well-ventilated with proper airflow. Consider operating the printer in a dedicated space or using an enclosure with ventilation or an exhaust system to minimize exposure to airborne particles and odors.

2. Filament Safety

Filaments used in 3D printing can vary in composition, and some may release potentially harmful substances when heated. Read the manufacturer's guidelines for the filaments you use and choose high-quality, reputable brands. It's also important to store filaments properly to prevent moisture absorption, as it can affect print quality and potentially lead to safety issues.

3. Fire Safety

3D printers generate heat, and accidents such as electrical malfunctions or filament overheating can pose a fire hazard. Never leave a 3D printer unattended while it is in operation, especially for extended periods. Ensure that your printer is placed on a fire-resistant surface, away from flammable materials, and consider installing a smoke detector or fire extinguisher nearby as an extra precaution.

4. Electrical Safety

Like any electronic device, 3D printers require proper electrical safety measures. Make sure you use the correct power supply and follow the manufacturer's instructions for setup and usage. Avoid overloading electrical outlets and use surge protectors to safeguard against power fluctuations or voltage spikes.

5. Maintenance and Calibration

Regular maintenance and calibration of your 3D printer are crucial for optimal performance and safety. Follow the manufacturer's guidelines for cleaning, lubrication, and maintenance tasks. Keep the printer clean from debris or excess filament that can affect its operation and potentially lead to malfunctions.

6. Operator Safety

Personal safety is paramount when using a 3D printer. Avoid touching hot surfaces, such as the heated print bed or nozzle, during or immediately after printing. Use appropriate protective equipment, such as heat-resistant gloves or safety goggles, when handling hot components or working with certain materials.

7. Education and Training

Familiarize yourself with the specific safety recommendations provided by the manufacturer of your 3D printer. Educate yourself on proper usage, troubleshooting techniques, and emergency procedures. Stay updated with safety guidelines and industry best practices through reliable sources and communities dedicated to 3D printing.

By being aware of these safety considerations and taking necessary precautions, you can enjoy a safer and more secure 3D printing experience. Remember, safety should always be a priority, and it is essential to balance creativity with responsible usage to minimize risks and ensure the well-being of yourself and those around you.

6. Getting the Most Out of Your 3D Printer

A. Maintenance and Troubleshooting

As you delve into the world of 3D printing, it's important to understand that proper maintenance and troubleshooting are essential for ensuring consistent print quality and maximizing the lifespan of your printer. Now let’s explore key maintenance practices and offer troubleshooting tips to keep your 3D printer running smoothly.

Maintenance Tips:

1.Regular Cleaning

Regularly clean the print bed, nozzle, and extruder to prevent filament residue buildup and ensure optimal printing conditions. Use a soft cloth or sponge with isopropyl alcohol to clean the print bed and remove any adhesive residue. For the nozzle and extruder, gently remove any clogs or debris using a fine needle or specialized cleaning tools.

2.Lubrication

If your printer has moving parts, such as rods or lead screws, lubrication is crucial to minimize friction and ensure smooth movement. Consult your printer's manual to determine the appropriate lubricant and follow the recommended intervals for lubrication.

3.Check and Tighten Fasteners

Regularly inspect and tighten all screws, nuts, and bolts to maintain the structural integrity of your printer. Vibrations during printing can sometimes cause these components to loosen over time, so a quick check and tightening can prevent potential issues.

4.Filament Storage

Proper filament storage is essential for maintaining its quality. Store your filament in a cool, dry place, ideally in an airtight container or a sealed bag with desiccant packs to prevent moisture absorption. Moisture-contaminated filament can lead to poor print quality and clogging.

5.Bed Leveling

Periodically check and recalibrate your print bed to ensure optimal leveling. Proper bed leveling promotes good adhesion and prevents uneven prints. Follow your printer's instructions to adjust the bed and achieve a level surface.

6.Fan Maintenance

Check and clean the cooling fans regularly to ensure efficient cooling during printing. Dust or debris can accumulate on the fan blades, hindering their performance. Use compressed air or a small brush to gently clean the fans and keep them free from obstructions.

7.Belt Tension

Proper belt tension is crucial for accurate and smooth movements of the printer's axes. Check the tension of the belts and adjust them if necessary. A loose belt can result in print artifacts or skewed prints, while an overly tight belt can strain the motor and affect print quality.

8.Print Bed Surface Replacement

Over time, the print bed surface may wear out or become damaged. If you notice significant scratches, unevenness, or poor adhesion, consider replacing the print bed surface with a new one. Many printers offer removable build surfaces that can be easily replaced.

9.Nozzle Replacement

The nozzle is subject to wear and tear, especially if you frequently print with abrasive filaments. If you notice degraded print quality or experience difficulties in extrusion even after cleaning, it may be necessary to replace the nozzle. Consult your printer's manual or manufacturer's instructions for guidance on the nozzle replacement process.

10.Firmware Updates

Stay up to date with the latest firmware releases for your 3D printer. Manufacturers often release firmware updates that can improve performance, fix bugs, and add new features. Check the manufacturer's website or community forums regularly for any available updates and follow the instructions for firmware installation.

11.Belt and Pulley Maintenance

Inspect the belts and pulleys of your printer for any signs of wear, such as fraying or stretching. Replace any worn-out belts to maintain precise movement. Additionally, ensure that the pulleys are clean and properly aligned. Misaligned pulleys can cause inconsistent movements and affect print quality.

12.Extruder Calibration

Periodically calibrate your extruder to ensure accurate filament extrusion. Calibration involves measuring the actual amount of filament being extruded and adjusting the extruder steps per millimeter (E-steps) accordingly. This helps prevent under or over-extrusion issues that can affect the dimensional accuracy of your prints.

13.Nozzle Height Adjustment

Pay attention to the nozzle height or the distance between the nozzle and the print bed. Ensuring the proper nozzle height is crucial for achieving good adhesion and print quality. Follow your printer's instructions for adjusting the nozzle height and perform regular checks to maintain the correct distance.

14.Cooling Fan Upkeep

Check the cooling fan(s) responsible for cooling the printed object during the printing process. Make sure the fan is spinning properly and free from obstructions. If necessary, clean the fan blades using compressed air or a small brush to remove any accumulated dust or debris.

15.Power and Cable Management

Regularly inspect the power cables and connections of your 3D printer. Ensure that the cables are not frayed or damaged, and that the connections are secure. Poorly managed cables can pose safety risks and may interfere with the printer's operation. Consider using cable management solutions to keep cables organized and protected.

16.Print Bed Adhesive Renewal

If you're using adhesive substances like glue sticks or adhesive sprays for bed adhesion, periodically renew the adhesive layer. Over time, the adhesive may become less effective, resulting in poor print adhesion. Clean the bed surface and reapply a fresh layer of adhesive according to the manufacturer's recommendations.

17.Backup and Archive Print Files

It's a good practice to back up your important print files and models. Create regular backups of your design files on external storage devices or cloud services. This ensures that you have copies of your designs in case of accidental loss or corruption.

18.Ongoing Learning and Skill Development

Stay engaged with the 3D printing community and continue learning about new techniques, materials, and troubleshooting tips. Online forums, YouTube tutorials, and instructional resources can help you enhance your knowledge and skills, enabling you to maximize the potential of your 3D printer.

Troubleshooting Tips:

1.Print Quality Issues

If you encounter issues with print quality, such as layer shifting, stringing, or inconsistent layers, start by checking the print bed leveling, nozzle height, and filament diameter settings. Ensure that the print surface is clean and properly prepared. Adjusting these settings can often resolve many common print quality issues.

2.Filament Jamming or Clogging

Filament jams or clogs can occur due to various factors, including improper filament feeding, insufficient cooling, or debris in the nozzle. If you encounter a jam, pause the print and follow the manufacturer's instructions for unclogging. Clear any obstructions, clean the nozzle, and reload the filament before resuming printing.

3.Adhesion Problems

If prints do not adhere properly to the print bed, ensure that the bed is clean and level. Adjust the print bed temperature and use appropriate adhesion aids like glue sticks, painter's tape, or specialized adhesive sheets. Experiment with different bed temperatures and adhesion methods to find the best solution for your specific filament and print surface combination.

4.Connectivity and Firmware Issues

If you experience connectivity problems or encounter issues with the printer's firmware, start by checking the cable connections and ensuring that the printer's firmware is up to date. Check for any available firmware updates from the manufacturer's website and follow the instructions to install them.

5.Nozzle Blockages

If the nozzle becomes blocked during a print or fails to extrude filament properly, it may be necessary to perform a cold pull or atomic pull procedure to remove any debris or clogs. Consult your printer's manual or manufacturer's website for specific instructions on how to perform this maintenance task.

6.Warping and Lifting

Warping and lifting of prints from the print bed can occur due to improper bed leveling or inadequate adhesion. Ensure that the print bed is leveled correctly and try adjusting the print bed temperature, increasing the use of adhesion aids, or using a heated enclosure to minimize temperature fluctuations.

7.Inconsistent Extrusion

If you notice inconsistent extrusion during a print, it could be due to a partial clog or a feeding issue. Check that the filament is loaded correctly, examine the extruder gear for any debris, and ensure the filament is feeding smoothly. Clearing any clogs and ensuring proper filament feeding can help resolve this issue.

8.Z-Axis Artifacts

If you encounter visible artifacts or irregularities in the Z-axis direction, such as layer shifts or inconsistent layer heights, check for any mechanical issues such as loose screws or damaged lead screws. Tighten any loose components and ensure smooth movement of the Z-axis.

9.Overheating

Continuous printing sessions or high ambient temperatures can cause overheating of the printer's components. If you notice issues like filament jamming, layer shifting, or irregular extrusion, monitor the temperature of the printer and its surroundings. Consider installing additional cooling fans or using external cooling solutions to manage the heat.

10.Error Messages

Pay attention to error messages displayed by your printer or through the software interface. Error messages can provide valuable information about specific issues, such as temperature deviations, communication errors, or filament detection problems. Consult the printer's manual or the manufacturer's support resources for guidance on troubleshooting specific error messages.

By implementing regular maintenance practices and applying troubleshooting techniques, you can ensure the longevity and optimal performance of your 3D printer. Don't hesitate to seek assistance from the 3D printing community or reach out to the manufacturer's support team when encountering persistent issues. With time and experience, you'll become adept at maintaining and troubleshooting your printer, enabling you to enjoy smooth and successful 3D printing sessions.

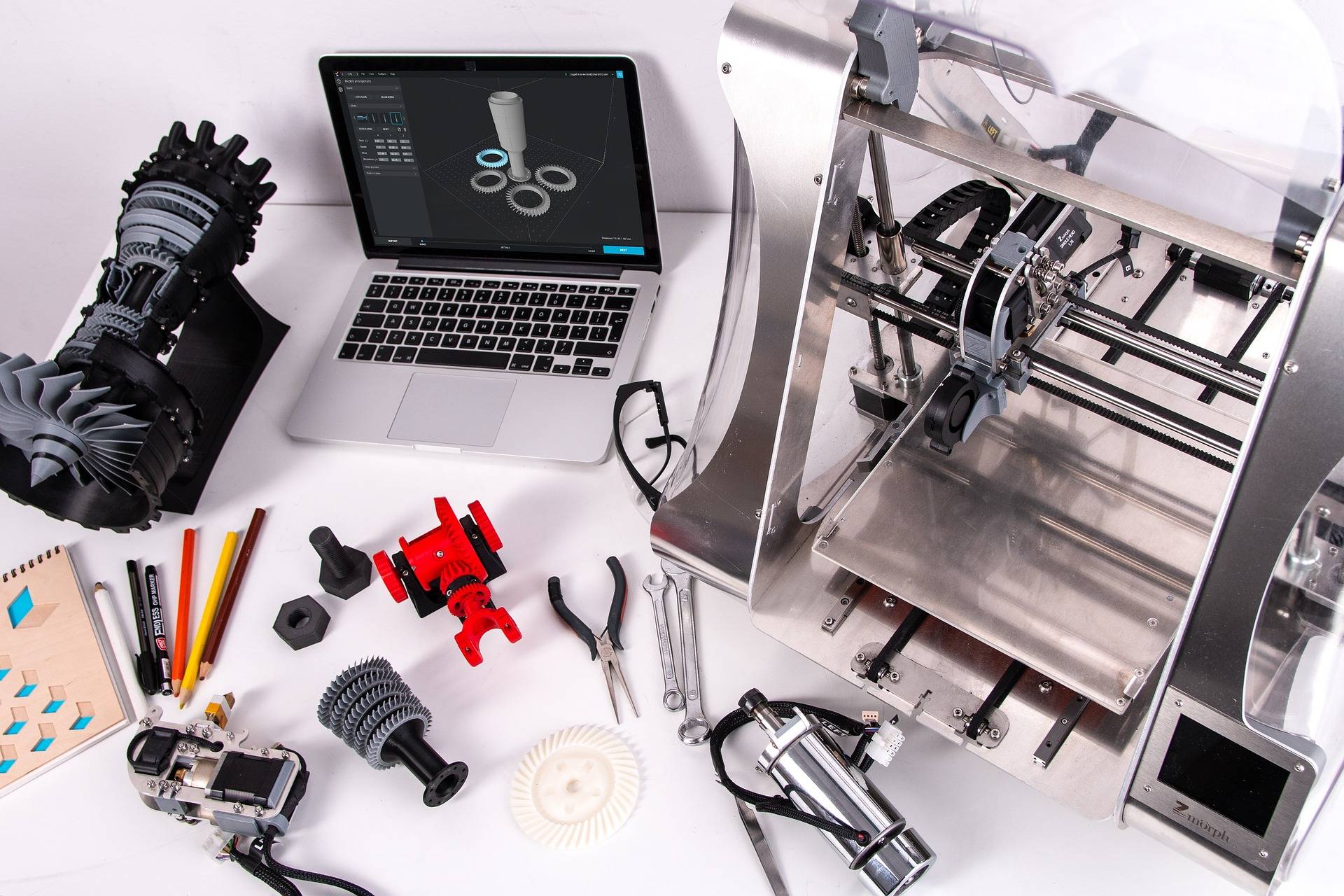

B. Best software and design tools for 3D printing

Having the right software and design tools can significantly enhance your creativity and streamline your printing process. From designing intricate models to preparing them for printing, the software you choose plays a vital role in achieving high-quality prints.

1.Tinkercad

Tinkercad is a popular entry-level software that offers a user-friendly interface and powerful design capabilities. It allows you to create 3D models by combining basic shapes, resizing and positioning them, and adding custom details. Tinkercad's intuitive drag-and-drop functionality makes it an ideal choice for beginners and hobbyists.

2.Fusion 360

Fusion 360 is a comprehensive 3D modeling and CAD (Computer-Aided Design) software developed by Autodesk. It offers advanced features for designing complex models and supports parametric modeling, which enables you to easily modify dimensions and features of your designs. Fusion 360 also provides powerful simulation tools to test the functionality of your designs before printing.

3.Blender

Blender is a versatile open-source 3D modeling software that is widely used in various industries, including animation, visual effects, and game development. While it has a steep learning curve, Blender offers extensive modeling tools and allows for intricate design creation. It also supports sculpting, rigging, and animation, making it a comprehensive tool for advanced users.

4.Meshmixer

Meshmixer is a powerful software for working with 3D mesh models. It allows you to manipulate, modify, and repair meshes to prepare them for 3D printing. With Meshmixer, you can perform operations such as mesh smoothing, hollowing, and adding supports. It also offers advanced features like remeshing and mesh analysis, ensuring your models are optimized for successful printing.

5.Simplify3D

Simplify3D is a professional-grade software known for its advanced slicing capabilities. It provides extensive control over print settings, allowing you to optimize parameters such as layer height, infill density, and support structures. Simplify3D supports a wide range of 3D printers and offers features like sequential printing and customizable print profiles, enabling you to achieve precise and efficient prints.

6.Cura

Cura is a popular open-source slicing software developed by Ultimaker. It offers a user-friendly interface and a wide range of customization options. Cura supports multiple file formats, provides extensive print settings, and incorporates features like tree supports, variable layer height, and mesh fixes. With its active community and regular updates, Cura remains a reliable choice for both beginners and experienced users.

7.PrusaSlicer

PrusaSlicer, developed by Prusa Research, is another powerful slicing software tailored for Prusa 3D printers. It offers an intuitive interface, comprehensive print settings, and advanced features like automatic variable layer height and adaptive layer cooling. PrusaSlicer also provides profiles specifically optimized for Prusa printers, ensuring seamless integration and exceptional print quality.

Remember to consult the software documentation and online tutorials to familiarize yourself with the features and functionalities of these tools. Experimentation and practice will help you unleash your creativity and master the art of 3D printing. Whether you're a beginner or an experienced enthusiast, the right software and design tools will empower you to transform your ideas into tangible and remarkable 3D prints.

C. Community resources and forums for 3D printing enthusiasts

Being part of a community of like-minded individuals can greatly enhance your 3D printing journey. Engaging with fellow enthusiasts, sharing knowledge, and seeking advice from experienced users can provide valuable insights and help you overcome challenges along the way. Some of the top community resources and forums are listed here where 3D printing enthusiasts gather, exchange ideas, and support each other.

1.Thingiverse

Thingiverse is a popular online platform that serves as a hub for sharing 3D printable files. It features an extensive collection of user-created designs, ranging from practical objects to artistic creations. You can browse through the vast library, download models, and even upload your own designs to contribute to the community. The platform also allows users to engage in discussions, ask questions, and provide feedback on designs.

2.PrusaPrinters

PrusaPrinters is a community-driven platform specifically tailored for users of Prusa Research 3D printers. It offers a rich collection of 3D models, firmware updates, and printer settings optimized for Prusa machines. The platform also hosts forums where users can seek advice, discuss troubleshooting techniques, and showcase their prints. PrusaPrinters is an excellent resource for Prusa owners, providing a supportive community and a wealth of knowledge.

3.Reddit /r/3Dprinting

Reddit's /r/3Dprinting subreddit is a vibrant community where 3D printing enthusiasts from all backgrounds come together. It serves as a central hub for discussions, news, troubleshooting, and sharing of 3D prints. You can find valuable insights, learn from experienced users, and participate in engaging conversations. The community also organizes events, contests, and AMAs (Ask Me Anything) with industry experts, fostering a collaborative and dynamic environment.

4.RepRap Forums

The RepRap Forums are dedicated to the RepRap movement, which focuses on open-source 3D printers. These forums have been a cornerstone of the 3D printing community for many years and are an excellent resource for troubleshooting, project sharing, and technical discussions. The community members are known for their helpfulness and willingness to assist newcomers, making it a great place to seek guidance and share experiences.

5.Facebook Groups

Facebook hosts numerous 3D printing groups catering to different interests, printer brands, and geographical regions. These groups provide platforms for users to connect, share their prints, ask questions, and receive support. Some groups are specialized in specific niches like cosplay, miniature modeling, or engineering applications. Searching for 3D printing-related keywords on Facebook can lead you to active communities that align with your interests.

6.Meetup

Meetup is a platform that facilitates in-person gatherings and events based on shared interests. It offers the opportunity to connect with local 3D printing enthusiasts, attend workshops, and join maker spaces or fab labs. Meetup allows you to build relationships within your local community, collaborate on projects, and learn from experienced individuals. Exploring the platform can help you discover nearby events and meet fellow enthusiasts face-to-face.

These community resources and forums are just a starting point for your exploration of the vast 3D printing community. Remember to engage actively, ask questions, share your experiences, and respect the contributions of others. By immersing yourself in these communities, you'll not only expand your knowledge but also forge meaningful connections and foster a lifelong passion for 3D printing.

D. Sharing Your Creations

As a 3D printing enthusiast, one of the most rewarding aspects is sharing your creations with the world. Whether you've designed functional objects, artistic pieces, or innovative prototypes, showcasing your 3D printing projects allows you to inspire others, receive feedback, and become an active participant in the vibrant maker community.

1.Social Media Platforms

Social media platforms such as Instagram, Twitter, and Facebook provide a convenient way to share your 3D printing projects with a broad audience. You can create dedicated accounts or hashtags to showcase your work and connect with other enthusiasts. By posting high-quality photos or videos of your prints, providing insights into the design process, and engaging in discussions, you can gain followers, inspire others, and receive valuable feedback.

2.Online Portfolio and Blogs

Creating an online portfolio or blog dedicated to your 3D printing projects allows you to showcase your work in a more comprehensive and organized manner. Platforms like WordPress, Wix, or Squarespace offer user-friendly templates for designing your portfolio or blog. You can showcase your prints, provide detailed descriptions, document your design process, and even offer tutorials or insights into your techniques. This approach allows you to have a centralized platform to direct interested individuals and establish your presence as a 3D printing enthusiast.

3.Maker Communities and Forums

Engaging with dedicated maker communities and forums is another effective way to share your projects and connect with fellow enthusiasts. Platforms such as Instructables, Hackaday, or Make: Community provide spaces to document your projects in a step-by-step manner, offering instructions, images, and even videos. These communities appreciate the sharing of knowledge and encourage others to replicate or build upon your designs.

4.Local Exhibitions and Maker Faires

Participating in local exhibitions, maker fairs, or other maker events can provide an opportunity to showcase your 3D printing projects to a live audience. These events often attract individuals with a passion for making and innovation. Setting up a booth or display area allows you to engage directly with visitors, explain your projects, and receive real-time feedback. It's also an excellent opportunity to network with other makers, share ideas, and gain inspiration for future projects.

5.Online 3D Printing Platforms

Several online platforms are specifically designed for sharing and distributing 3D printable designs. Websites like MyMiniFactory, Cults3D, and Pinshape allow you to upload and share your designs with a global community of 3D printing enthusiasts. Users can download your files, provide feedback, and even remix or modify your designs. These platforms provide exposure and recognition within the 3D printing community and can potentially lead to collaborations or partnerships.

Sharing and showcasing your 3D printing projects not only allows you to celebrate your achievements but also contributes to the overall growth and inspiration of the maker community. Whether you choose social media platforms, online portfolios, maker communities, local exhibitions, or specialized online platforms, the key is to actively engage, provide quality content, and foster meaningful interactions. By sharing your knowledge, techniques, and experiences, you become an integral part of the 3D printing ecosystem, encouraging others to explore and push the boundaries of this exciting technology.

7. How can I make money with a laser engraver?

If you own a 3D printer, you have a powerful tool at your disposal not only for personal projects but also for potential profit opportunities. 3D printing opens up a wide range of possibilities to turn your creativity and technical skills into a lucrative venture.We'll explore various avenues where you can leverage your 3D printer to generate income and explore the exciting world of entrepreneurship.

1. Customized Product Manufacturing

One of the most popular ways to generate profit with a 3D printer is by offering customized product manufacturing. With the ability to create unique and personalized items, you can cater to niche markets or individual customers looking for bespoke products. Whether it's customized phone cases, jewelry, home decor, or even specialized parts, the possibilities are endless. Marketplaces like Etsy or local craft fairs are excellent platforms to showcase and sell your creations.

2. Prototyping and Product Development

Businesses often require prototypes and product development services to bring their ideas to life. With your 3D printer, you can offer these services, helping entrepreneurs and startups visualize their concepts and refine their designs before investing in mass production. Collaborating with local businesses, designers, or even engineering firms can provide a steady stream of projects and income.

3. Replacement Parts and Accessories

Another profitable avenue is producing replacement parts and accessories for various industries. From obsolete or hard-to-find parts to custom-fit components, 3D printing allows you to meet the demand for these items. Researching niche markets and establishing partnerships with businesses in need of specialized parts can create a steady revenue stream.

4. Educational Workshops and Training

If you have expertise in 3D printing and design, consider offering educational workshops and training sessions. Many individuals and businesses are eager to learn the ins and outs of 3D printing. By sharing your knowledge and conducting hands-on training, you can provide value to aspiring enthusiasts, students, or professionals who want to enhance their skills. These workshops can be conducted in-person or even online through platforms like Udemy or Skillshare.

5. Licensing and Royalties

If you are a skilled designer, you can monetize your designs by licensing them to manufacturers or selling them on specialized 3D printing platforms. By creating a portfolio of high-quality and in-demand designs, you can earn passive income through licensing agreements or royalties. Collaborating with companies interested in producing and selling your designs can help reach a broader market.

6. 3D Printing Services

Apart from manufacturing products, you can also offer 3D printing services to individuals or businesses that do not own their own 3D printers. By providing print-on-demand services, you can cater to those who need occasional or one-time prints. This can include architectural models, prototypes, figurines, or any other 3D printable objects. Building a reliable and efficient service can result in recurring clients and a steady income stream.

7. Design and Sell STL Files

If you have a knack for 3D design, you can create and sell STL files online. These digital designs can be purchased by individuals or businesses looking to print their own objects. Consider focusing on popular categories like gaming accessories, cosplay props, collectibles, or unique home decor items. Platforms like MyMiniFactory and CGTrader allow you to sell your designs and earn royalties for each sale.

8. Customized Merchandise for Events and Businesses

Many events, conferences, and businesses seek customized merchandise to promote their brand or create memorable experiences. You can offer services to design and print personalized items like keychains, badges, signage, or promotional products. Establishing partnerships with event planners, marketing agencies, or local businesses can provide a consistent stream of orders.

9. 3D Scanning and Replication

Combine 3D scanning technology with your printer to offer replication services. Individuals may have sentimental objects or artifacts they wish to replicate, whether for preservation or replacement purposes. By providing 3D scanning and printing services, you can help recreate these items with precision and accuracy.

10. Architectural Models and Visualizations

Architects, real estate developers, and urban planners often require accurate and detailed architectural models for presentations and visualizations. Utilize your 3D printer to offer high-quality, scale models of buildings, landscapes, or interior spaces. Networking with professionals in the construction and architecture industry can lead to lucrative partnerships.

11. Personalized Gifts and Keepsakes

Tap into the gift market by offering personalized and unique 3D printed items. Wedding favors, customized figurines, personalized photo frames, or engraved objects make thoughtful gifts for special occasions. Establish an online presence through social media or dedicated websites to attract customers seeking personalized and one-of-a-kind gifts.

12. Medical and Dental Applications

Explore opportunities within the medical and dental fields. 3D printing is revolutionizing healthcare by enabling the production of patient-specific implants, anatomical models, and surgical guides. Collaborating with medical professionals, clinics, or dental laboratories can open doors to providing specialized 3D printing services.

Conclusion

when it comes to buying a 3D printer, it is important to consider your needs, budget, and experience level. By following the tips and guidelines outlined in this buying guide, you can make an informed decision and find the perfect 3D printer for you. If you're looking for a reliable and affordable 3D printer, be sure to check out GearBerry's website. We offer a wide range of high-quality 3D printers from top brands, as well as accessories and supplies to help you get the most out of your printer. Don't hesitate to visit our website and start exploring our selection today!